INFLATABLE

BOATS

|

|

Remember safety is your own responsibility.

Altering boats will void manufacturer's warranties. You must register

the vessel prior to installing any type of motor. Wear PFD at all

times! Check with your local laws and customs before doing any work.

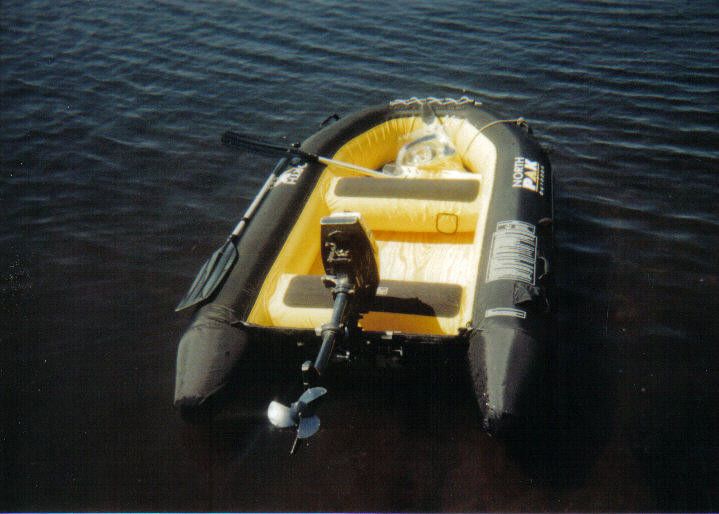

I

purchased this pontoon boat on eBay several years ago for $125 plus $25

S&H. I was quite excited when I received the package a couple of

days later. I drove down to a local pond and inflated it put all my

gear inside and cast off. My initial excitement immediately waned. The

boat sagged the transom buckled, rowing was difficult and when I turned

on the trolling motor I had to hold on to it to keep it from ripping

the back end off the boat.

|

I

realized the part of the problem was the craft did not have a solid

bottom, passenger and gear warped the boat's sleek lines. I decided to

fix the problem and build this into the boat it was meant to be.

I

made templates of the boat's bottom by tracing the outline onto craft

paper. Next I cut 1/4 inch plywood using the paper template as a guide.

I rounded off all corners to prevent any punctures to the boat.

When

I tried to slip the sheet of plywood inside the boat it seemed as

though the tight fit might tear the canvas floor. This was quickly

solved by cutting the sheet where it starts to narrow, thereby

facilitating insertion.

|

Once

again I rounded off all corners to prevent any damage to the canvas.

The two sections of plywood were joined together using aluminum

channel. The arrangement worked very well. Once

again I rounded off all corners to prevent any damage to the canvas.

The two sections of plywood were joined together using aluminum

channel. The arrangement worked very well.

The

Boat came with a wooden transom. I since replaced the original with the

same stock used to build the floor.

I

also built two L shaped brackets of thick aluminum stock to reinforce

the transom. After a few uses it became clear they had to be replaced

by stronger material.. |

Before

taking the boat out I sanded the plywood sections and coated them with

polyurethane. I have since given several coats of the stuff.

The

picture on the left shows the end result. The craft retained it's sleek

lines even when carrying two passengers and equipment. I also used a

2.2 HP gas motor on it an could probably use an even bigger motor

safely.

I

done more experiments to improve performance of the vessel such as

adhering an sock tube to the bottom of the plywood sheets. When

inflated the canvas floor beneath it will assume a V shape giving the

craft greater stability and a noticeable difference in speed.

The

craft is so light I carry it in and out of the water with one hand

while my free hand carries the outboard motor.

After

several uses the aluminum brackets used to reinforce the transom

started to loose their rigidity. I replaced them with steel heavy duty

shelving brackets from Home Depot. They have worked well so far

|

|

|

Using

the lessons I learned from the previous project I decided to tackle my

Sevylor boat.

Originally

these boats were intended to be powered by low thrust motors sold by

Sevylor. Unfortunately the company stopped selling both the motor and

the transom kit.

I

did find one boat for sale with a transom mount but was disappointed

with it. What a piece of junk. It was too flimsy and the design

actually hindered performance. the rods extended under the boat

creating drag. Anyone who has ever seen the transom mounts sold by the

makers of inflatable boats will agree with me on this.

My

own transom mount was built of simple to make PVC pipe with a 1X4 "

length of wood mounted horizontally. The pipe only reach down to the

water line and should not create any drag. My

own transom mount was built of simple to make PVC pipe with a 1X4 "

length of wood mounted horizontally. The pipe only reach down to the

water line and should not create any drag.

The

mount loops over the air chamber and attaches to a floor which was

built of pink construction foam layered in fiberglass. Make sure you

use epoxy resin when making foam core projects, other types will melt

foam ruining your project.

The

battery case was attached to the PVC tubing to provide added security

to the design. I was afraid the foam core did not provide a solid

foundation to the mount. The weight of the battery insured the mount

did not detach from the floor.

The

foam core floor is installed prior to inflating the craft. When

inflated the air chambers hold the floor in place.

The

design worked very well. The only drawback was con fort. The Sevylor's

inflatable floor was now beneath the hard foam core.

Instead

of the wimpy Sevylor motor I used a Stealth 25 lb thrust motor.

I

fell in the water once and got back on the boat without much trouble,

I'm sure the same would not have been said had I not installed the

floor. Just imagine trying to get back onto a boat that bends as you

are trying to climb back in. I was wearing my PFD. Without it I

probably would have panicked.

Look

how sleek and rigid the craft looks!

These

boats are so versatile, they go where no other boats will. Secluded

coves, narrow channels, shallow ponds... Are all accessible with these

very inexpensive craft.

|

SAILING CANOE

|

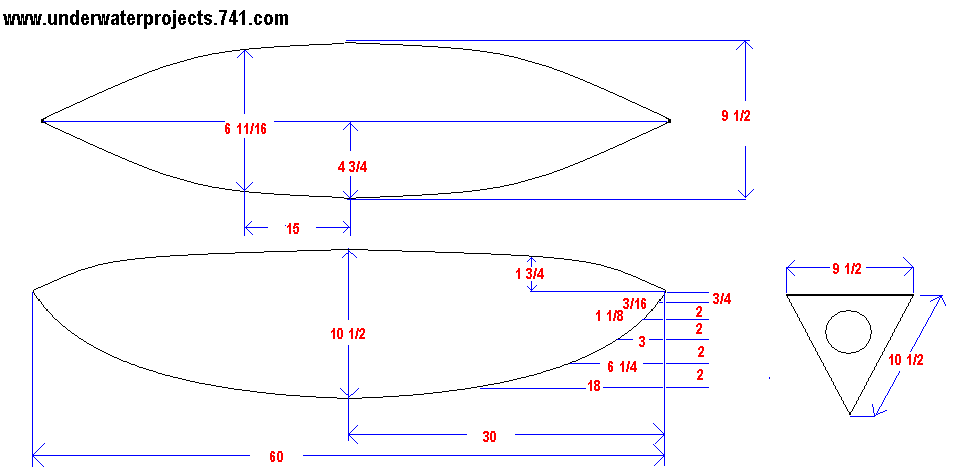

RIGHT CLICK ON THE PICTURE ABOVE AND DOWNLOAD IT THEN PRINT IT OUT

|

WATERMAKER PLANS

|

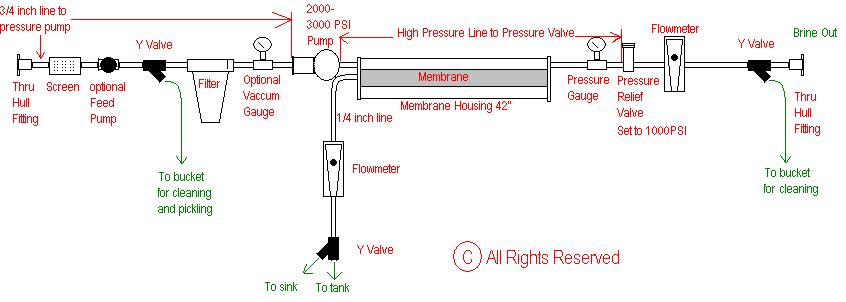

The

diagram shown is a schematic. The parts are all commonplace and easy to

obtain from most marine hardware suppliers. The diagram is self

explanatory but the following is a quick run through of the component

parts:

1.The

thru hull fitting should ideally be a dedicated three quarter inch

fitting.

2.A

sea strainer or screen connected to the hull fitting by a three quarter

inch line, which will continue on to the pressure pump.

3.After

the screen, which is intended to remove solids such as seaweed, is an

optional feed pump, whose purpose is to ensure that airlocks do not

occur in the system.

4.Following

the feed pump is a Y-valve with a free tail, which is used for cleaning

and pickling the system. This tail usually has a small filter on the

bottom, and is inserted in a bucket with the pickling solution.

5.This

is followed by a filter which should be a 20-30 micron filter. Some

filter housings have a by-pass valve which allows you to eliminate the

Y-valve and have the cleaning and pickling pipe going to this system

directly.

6.The

filter is followed by an optional vacuum gauge, followed by

7.A

1,500 psi high pressure pump, not 2-3000 psi as stated in the diagram,

which will be run at 800 psi and can be either electrically or engine

driven. CAT pumps are suitable for this purpose.

8.The

membrane and pressure vessel, which in this case is a 42 inch long

system, is connected to the pump by a high pressure line, which

continues to the pressure valve

9.From

the membrane, a quarter inch plastic line goes through a flow meter to

a Y-valve which can be connected to the water tank for drinkable water,

and optionally, to the sink.

10.From

the other side of the membrane and pressure vessel connected by a high

pressure line is a pressure gauge to 1,000 psi, followed by a

11.Pressure

valve with optional bypass at 1,000psi.

12.From

this valve, a quarter inch line continues through a flow meter and a

13.Y-valve

which will discharge overboard, or to the cleaning bucket.

It

is quite a simple unit to build, and with proper maintenance should

give 100 litres per hour for many years,

|

FOR FURTHER STUDY

CHECK OUT

MY EBOOK REVERSE OSMOSIS

Watermaker

Plans

Watermaker Page

|

|